Litšobotsi tsa li-insulator tsa ceramic

Ho ea ka litšobotsi tsa kopo, li-tubes tsa ceramic tsa motlakase li ka aroloa ka: Li-insulators bakeng sa mela, li-insulators bakeng sa liteishene tsa motlakase kapa lisebelisoa tsa motlakase;E ka aroloa ka insulator ea ka tlung le insulator ea ka ntle ho latela tikoloho ea kopo;Ceramic, letsopa la tlhaho e le thepa e tala, thepa e tsoakiloeng, workpiece Li-ceramics tse tloaelehileng li sebelisoa bakeng sa tšebeliso ea letsatsi le letsatsi, bohloeki ba mohaho, lisebelisoa tsa motlakase (insulation), indasteri ea lik'hemik'hale le lirafshoa tse khethehileng - li-capacitor, piezoelectric, magnetic, electro-optic le li-ceramic tsa mocheso o phahameng oa mocheso. hangata li aroloa ho latela sebopeho sa sehlahisoa, boemo ba motlakase le tikoloho ea ts'ebeliso ea lirafshoa tsa motlakase.Ho ea ka sebopeho sa sehlahisoa, se ka aroloa ka: "disc suspension insulator", "pin insulator", "rod insulator", "hollow insulator", joalo-joalo;Ho ea ka boemo ba motlakase, e ka aroloa ka li-insulators tsa "low-voltage" (AC 1000 V le ka tlase, DC 1500 V le ka tlase) le li-insulators tse phahameng (AC 1000 V le ka holimo, DC 1500 V le holimo).Har'a li-insulators tse phahameng haholo, ho na le motlakase o phahameng haholo (AC 330kV le 500 kV, DC 500 kV) le motlakase o phahameng haholo (AC 750kV le 1000 kV, DC 800 kV).

Mofuta oa li-ceramics tse sebetsang tseo resistivity ea tsona e fetohang haholo ka mocheso.Ho ea ka litšobotsi tsa mocheso oa ho hanyetsa, e arotsoe ka mocheso o motle oa mocheso (PTC) Thermal Ceramics le mocheso o fosahetseng oa mocheso (NTC) Thermal Ceramics.

The resistivity of Thermal Ceramics e nang le coefficient e ntle ea mocheso e fokotseha haholo ka ho eketseha ha mocheso.Tšobotsi ena e hlokoa ke thepa ea motlakase ea lijo-thollo le meeli ea lijo-thollo mohahong oa li-ceramics.Ke li-ceramics feela tse nang le lithollo tse semiconducted ka botlalo le ho kenella ho hlokahalang meeling ea lijo-thollo tse ka bang le tšobotsi ena.Thermosensitive ceramics tse sebelisoang hangata ke lirafshoa tsa BaTiO tse nang le litšila tse tšehetsang le lisebelisoa sebakeng se fokotsehileng.Haholo-holo li sebelisoa ho etsa mefuta ea matla e feto-fetohang ea li-thermosensitive ceramic resistors, li-limiter tsa hona joale, joalo-joalo.

The resistivity ea mocheso o mobe coefficient thermosensitive ceramics e eketseha ka sekhahla ka ho eketseha ha mocheso.Bongata ba li-ceramics tsena ke litharollo tse tiileng tsa tšepe tse nang le oxide e tiileng e nang le sebopeho sa spinel, ke hore, li-oxide tse ngata tse nang le tšepe e le 'ngoe kapa tse ngata tse fetohang (joalo ka Mn, Cu, Ni, Fe, joalo-joalo).Foromo e akaretsang ea lik'hemik'hale ke AB2O4, 'me mochini oa eona oa ho tsamaisa o fapana ho ea ka sebopeho, sebopeho le mokhoa oa semiconductor.Li-ceramics tsa mocheso tse mpe tsa mocheso li sebelisoa haholo-holo bakeng sa tekanyo ea mocheso le matšeliso a mocheso.Ho phaella moo, ho na le li-ceramics tsa mocheso tseo resistivity ea tsona e fetohang ka mokhoa o lumellanang le ho eketseha ha mocheso, le Thermal Ceramics eo resistivity ea eona e fetohang hape ka mocheso o itseng oa bohlokoa.Ea morao-rao e sebelisetsoa ho hlahisa lisebelisoa tsa phepelo ea motlakase, kahoo e bitsoa phepelo ea motlakase Thermal Ceramics.Ho ea ka mefuta ea mocheso, li-ceramics tsa mocheso li arotsoe ka mocheso o tlase (4 ~ 20K, 20 ~ 80K, 77 ~ 300K, joalo-joalo), mocheso o mahareng (o tsejoang hape e le standardization, - 60 ~ 300 ℃) le mocheso o phahameng (300 ~ 1000 ℃).

Positive mocheso coefficient thermistor;li-ceramics tsa semiconductor;li-ceramics tsa ferroelectric;ntshetsopele

Kakaretso: ho latela litlaleho tsa lingoliloeng le boiphihlelo ts'ebetsong ea mosebetsi, lipatlisiso tsa tlhahiso, tlhahlobo ea ts'ebetso, litšobotsi tsa thepa le ts'ebeliso ea lirafshoa tsa PTC li hlalositsoe.

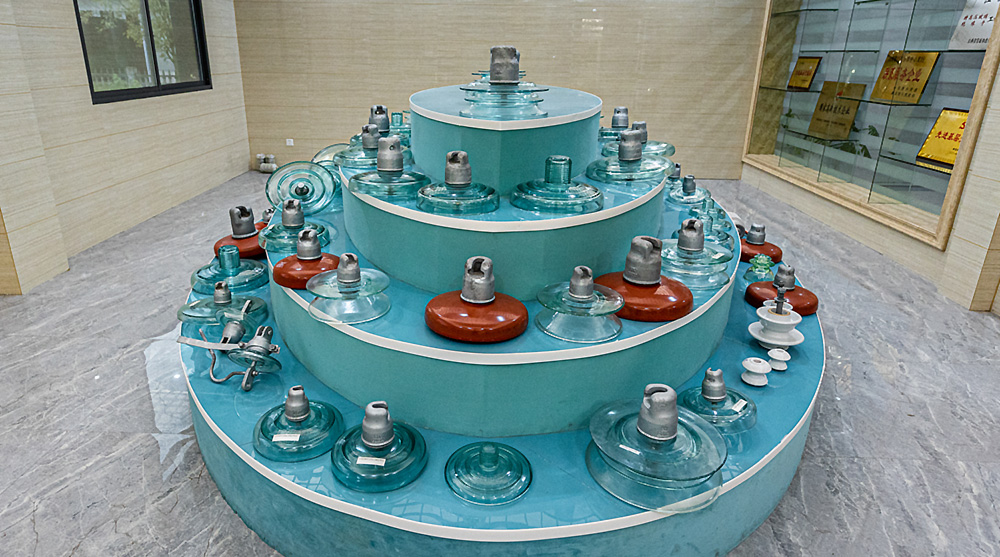

Johnson power, tšebeletso ea sebaka se le seng bakeng sa basebelisi ba matla ba lefats'e.Jiangxi Johnson Electric Co., Ltd. e hlahisa li-insulators tsa motlakase, li-insulators tsa porcelain, li-insulators tsa khalase, li-insulators tse kopantsoeng, li-insulators tsa mela, li-insulators tse emisitsoeng, li-insulators tsa pin, li-insulators tsa disc, li-insulators tsa tsitsipano, li-tšoarning tsa lehalima, li-disconnectors, li-transformer, li-switch switching, li-box substations, li-drop. fuse, lithapo le lisebelisoa tsa motlakase.Rea u amohela ho botsa.

Litšobotsi tsa insulator ea khalase

Insulator ea khalase e na le litšobotsi tse latelang:

(1) Matla a phahameng a mochini, 1 ~ 2 makhetlo a phahameng ho feta a insulator ea porcelain.

(2) Ts'ebetso e tsitsitse ebile ha e bonolo ho tsofala, mme ts'ebetso ea motlakase e phahame ho feta ea insulator ea porcelain.

(3) Ts'ebetso ea tlhahiso e nyane, potoloho ea tlhahiso e khuts'oane, e loketse tlhahiso ea mochini le othomathiki, 'me katleho ea tlhahiso e phahame.

(4) Ka lebaka la ho pepeseha ha insulator ea khalase, ho bonolo ho fumana mapetsong a manyane le mefokolo e fapaneng ea kahare kapa tšenyo nakong ea tlhahlobo ea kantle.

(5) Haeba ho na le mefokolo e fapaneng 'meleng oa khalase ea insulator, khalase e tla robeha ka bo eona, e bitsoang "self breaking".Ka mor'a hore insulator e robehe, hamore e setseng ea sekoahelo sa tšepe e ntse e boloka matla a itseng a mochine 'me e fanyehiloe moleng,' me mohala o ntse o ka tsoela pele ho sebetsa.Ha mohlahlobi oa mohala a hlahloba mohala, ho bonolo ho fumana insulator e robehileng ebe o nkela insulator e ncha ka nako.Hobane insulator ea khalase e na le litšoaneleho tsa "ho itšeha", ha ho hlokahale ho etsa tlhahlobo ea thibelo ho insulator nakong ea ts'ebetso ea mohala, e tlisang boiketlo bo boholo ts'ebetsong.

(6) Li-insulator tsa khalase li bobebe ka boima.Ka lebaka la ts'ebetso ea tlhahiso le mabaka a mang, sekhahla sa "self breaking" sa insulator ea khalase se phahame, e leng kotsi e bolaeang ea insulator ea khalase.

Mofuta oa insulator ea ho emisoa e kopantsoeng:

mofuta o tloaelehileng, mofuta o hananang le tšilafalo, mofuta oa DC, mofuta oa spherical, mofuta oa aerodynamic, mofuta oa terata ea fatše, bakeng sa sistimi ea likhokahano tse holimo tsa seporo sa motlakase.

1. Sehlahisoa sa insulator se kopantsoeng se entsoe ka likarolo tse tharo: khalase ea fiber epoxy resin pull-out rod, silicone rabara skirt ea sekhele le hardware.Sesepa sa sekhele sa silicone sa rabara se amohela mokhoa o kenyelletsoeng oa ente ea khatello, e rarollang bothata ba bohlokoa bo amang ho ts'epahala ha insulator e kopaneng, ho senyeha ha motlakase oa sebopeho.Mokhoa o tsoetseng pele ka ho fetisisa oa crimping o amoheloa bakeng sa ho hokahanya pakeng tsa molamu oa ho hula ka khalase le lisebelisoa, tse nang le mokhoa o feletseng oa ho lemoha phoso ea acoustic.E na le matla a phahameng, ponahalo e ntle, molumo o monyenyane le boima bo bobebe.Lisebelisoa tse entsoeng ka masenke li ka thibela mafome le ho bola, 'me li ka fapanyetsanoa le li-insulators tsa porcelain.Sebopeho se ka tšeptjoa, ha se senye mandrel, 'me se ka fana ka papali e feletseng ho matla a eona a mochine.

2. Ts'ebetso e phahameng ea motlakase le matla a phahameng a mechine.Matla a tsitsipano le a feto-fetohang a khalase ea epoxy e hulang ka ntle ka hare e phahame ka makhetlo a 2 ho feta ea tšepe e tloaelehileng le makhetlo a 8 ~ 10 ho feta a porcelain e matla a phahameng, e leng ho ntlafatsa ka katleho ho tšepahala ha ts'ebetso e sireletsehileng.

3. E na le khanyetso e ntle ea tšilafalo, khanyetso e ntle ea tšilafalo le khanyetso e matla ea tšilafalo ea flashover.Matla a eona a ho mamella mocheso le tšilafalo ea motlakase ke makhetlo a 2 ~ 2.5 a li-insulators tsa porcelain tse nang le sebaka se tšoanang sa creepage.Ntle le ho hloekisa, e ka sebetsa ka mokhoa o sireletsehileng libakeng tse silafetseng haholo.

4. Molumo o monyenyane, boima bo bobebe (feela 1 / 6 ~ 1 / 9 ea insulator ea porcelain ea sehlopha se tšoanang sa voltage), mohaho o bobebe le lipalangoang tse loketseng le ho kenya.

5. Sesepa sa sekhele sa rabara sa silicone se na le ts'ebetso e ntle ea hydrophobic.Sebopeho sa eona ka kakaretso se tiisa hore ho kenngoa ha ka hare ha ho amehe ke mongobo.Ha ho na tlhoko ea tlhahlobo le ho hloekisoa ho thibelang ho kenella kahare, e leng ho fokotsang mosebetsi oa tlhokomelo ea letsatsi le letsatsi.

6. E na le ts'ebetso e ntle ea ho tiisa le ho hanyetsa matla a matla a motlakase.Thepa ea moaparo oa sekhele e hanyetsana le ho lutla ha motlakase 'me e tšoaea ho fihla ho tma4 Level 5, e nang le khanyetso e ntle ea botsofali, ho hanyetsa kutu le ho hanyetsa mocheso o tlase, e ka sebelisoang sebakeng sa - 40 ℃ ~ - 50 ℃.

7. E na le ts'ebetso e matla ea ho hanyetsa le ho tsieleha ho ts'oenyeha, e ntle ea anti brittleness le creep resistance, ha ho bonolo ho robeha, ho khumama ho phahameng le matla a torsional, e ka mamella khatello ea ka hare, matla a matla a ho phatloha, 'me e ka fapanyetsanoa le porcelain le li-insulators tsa khalase.

8. Lisebelisoa tsa mechine le tsa motlakase tsa lihlopha tsa li-insulator tse kopantsoeng li molemo ho feta tsa porcelain insulator, tse nang le moeli o moholo oa tšireletso ea ts'ebetso.Ke sehlahisoa se ntlafalitsoeng bakeng sa mohala oa motlakase.

Litšobotsi tsa insulator e kopantsoeng

1. Boleng ba lefela ke ho itšeha 'me ho bonolo ho bo lemoha

Motsoako o leketlileng o na le litšobotsi tsa "zero value self breaking".Hafeela e ntse e hlokomeloa fatše kapa ka helikopta, ha ho hlokahale hore u hloelle palo ho lemoha sengoathoana, e leng se fokotsang matla a mosebetsi oa basebetsi.

Ka kenyelletso ea lihlahisoa tse tsoang moleng oa tlhahiso, sekhahla sa selemo le selemo sa ho itšeha ke 0.02-0.04%, se ka bolokang litšenyehelo tsa tlhokomelo ea mohala.Arc e ntle le khanyetso ea vibration.Ha e ntse e sebetsa, bokaholimo bo bocha ba khalase e chesitsoeng ke lehalima e ntse e le 'mele o boreleli oa khalase' me o na le lera le thata la ts'ireletso ea kahare.Ka hona, e ntse e boloka matla a lekaneng a ho koala le matla a mochine.

Koluoa ea lebelo e bakiloeng ke conductor icing e etsahetse hangata moleng oa 500 kV.Sesebelisoa sa ho emisoa se kopantsoeng ka mor'a hore mokhanni a phalle ha a na attenuation ts'ebetsong ea electromechanical.

2. Ts'ebetso e ntle ea ho itlhoekisa 'me ha ho bonolo ho tsofala

Ho ea ka pontšo e akaretsang ea lefapha la matla, khalase ea khalase ha e bonolo ho bokella tšilafalo le ho hloekisa habonolo, 'me mochine oa khalase o mathang moleng o ka boroa o hlatsuoa ka mor'a pula.

Kamehla u etse mohlala oa li-insulators tsa khalase meleng ea libaka tse tloaelehileng ho lekanya ts'ebetso ea electromechanical ka mor'a ts'ebetso.Boitsebiso bo bokelitsoeng ba likete bo bontša hore ts'ebetso ea electromechanical ea li-insulators tsa khalase ka mor'a lilemo tse 35 tsa ts'ebetso e hlile e lumellana le nakong ea ho pepa, 'me ha ho na ntho ea botsofali.

Bokhoni ba mantlha bo boholo, phepelo ea motlakase khoeleng e ts'oana, 'me khalase ea dielectric ea khalase ke 7-8, e leng se etsang hore insulator e kopaneng e be le matla a maholo le phepelo e tšoanang ea motlakase khoeleng, e thusang ho fokotsa matla. motlakase o tsamaisoang ke insulator haufi le lehlakore la conductor le lehlakore le thehileng, e le ho fokotsa tšitiso ea seea-le-moea, ho fokotsa tahlehelo ea corona le ho lelefatsa bophelo ba ts'ebeletso ea mochini oa khalase.Ts'ebetso ea ts'ebetso e pakile sena

Litšobotsi tsa ts'ebetso le maemo a ts'ebeletso ea insulator e kopaneng # litšobotsi tsa ts'ebetso ea insulator e kopaneng:

1. Molumo o monyenyane le boima bo bobebe, e leng hoo e ka bang 1 / 5 ~ 1 / 9 ea motlakase o tšoanang oa sehlopha sa porcelain, e leng se loketseng bakeng sa lipalangoang le ho kenya.

2. Insulator e kopantsoeng e na le matla a phahameng a mechine, mohaho o ka tšeptjoang, ts'ebetso e tsitsitseng le moeli o moholo bakeng sa ts'ebetso e sireletsehileng, e fanang ka tiiso bakeng sa mohala le ts'ebetso e sireletsehileng.

3. Insulator e kopantsoeng e na le ts'ebetso e phahameng ea motlakase.Sesepa sa sekhele sa rabara sa silicone se na le hydrophobicity e ntle le motsamao, ho hanyetsa tšilafalo e ntle le matla a matla a ho thibela tšilafalo.E ka sebetsa ka mokhoa o sireletsehileng libakeng tse silafetseng haholo ntle le ho hloekisa ka letsoho 'me e ka ba ntle ho tlhokomelo ea boleng ba zero.

4. Insulator e kopantsoeng e na le litšobotsi tsa ho hanyetsa acid le alkali, ho hanyetsa botsofali ba mocheso le ho hanyetsa motlakase, ts'ebetso e ntle ea ho tiisa, 'me e ka etsa bonnete ba hore ho kenngoa ha eona ka hare ha ho amehe ke mongobo.

5. Insulator e kopantsoeng e na le khanyetso e ntle ea brittleness, e matla e hanyetsanang le ts'oaetso 'me ha ho kotsi ea brittle fracture.

6. Li-insulators tse kopantsoeng li ka nkeloa sebaka 'me li ka fapanyetsanoa le li-insulators tsa porcelain.

Joang ho ahlola boleng ba insulator?

a.Tekanyetso ea ho hanyetsa ho ts'oara ho ts'oanelehang

(1) Ho hanyetsa ha li-insulator tse sa tsoa kenngoa ho tla ba kholo ho feta kapa ho lekana le 500m Ω.

(2) Ho hanyetsa ha insulator nakong ea ts'ebetso e tla ba kholo ho feta kapa ho lekana le 300m Ω.

b.Molao-motheo oa kahlolo ea ho senyeha ha insulator

(1) Haeba khanyetso ea insulator e ka tlase ho 300m Ω mme e kholo ho feta 240m Ω, e ka ahloloa e le insulator ea boleng bo tlase.

(2) Haeba insulator e hanyetsanang le eona e ka tlase ho 240m Ω, e ka nkoa e le "zero insulator".

Mokhoa ona ka kakaretso ha o sebelisoe ho leka ho hanyetsa ho kenella ha motsoako o kopaneng.

Li-insulators tse emisitsoeng li sebelisoa haholo tsamaisong ea matla.Li-insulators tsa FRP li na le nako e telele ea tšebeletso 'me li ratoa ke tsamaiso ea matla.Boleng ba li-insulators tse emisitsoeng 'marakeng ha bo lekane.Ho na le li-insulators tse fanyehiloeng hape tsa litšila tse rekisoang.Hoa hlokahala ho bapisa thepa ha u reka li-insulators tse emisitsoeng.Haeba u batla ho tseba ka kopano ea li-insulator tse emisitsoeng le ho fumana litšoantšo tsa likhokahanyo tse emisitsoeng, u amohelehile ho ikopanya le khamphani ea lisebelisoa tsa motlakase ea Joson, moetsi oa lisebelisoa tsa boleng bo holimo tse emisang.Matla a Josen a fana ka li-insulators tsa porcelain tse nang le matla a phahameng a motlakase, li-insulators tsa 330kV tse emisitsoeng, li-insulators tsa 500kV tse emisitsoeng, li-insulators tsa 10kV tse emisitsoeng, li-insulators tse thibelang tšilafalo, li-insulators tse tloaelehileng tse emisitsoeng, li-insulators tsa khalase tse emisitsoeng ka disk le tse emisitsoeng.

Nako ea poso: Apr-18-2022